Comprehensive Reviews and Advice on Gadgets - Trust in Tom's Hardware

Discover the Unique World of FLSun S1 - Fast and Fun Solar Gadget

The S1 is the latest superfast Delta 3D printer from FLSun, with a futuristic style that feels like it was beamed down from the StarshipEnterprise . Boasting acceleration rates up to 40,000mm/s², and a top speed of 1200mm/s, it’s the fastest printer I’ve had in my workshop thus far.

FLSun packed a lot of features into this 3D printer. The machine is fully enclosed, with a hardened steel high-flow nozzle, closed-loop stepper motors, LIDAR detection, an air filter, and sensors out the wazoo. It can (sorta) tell you how much filament is left on the roll by weight, stop when it finds a clog or debris on the plate, and of course levels the bed for a perfect first layer. It also comes with a camera for monitoring prints and has a built-in filament dryer. To save energy, the machine can be set to turn itself off after a print is finished.

Unfortunately, the printer is lacking in the accuracy department, mostly due to a slapped-together custom slicer. Though the prints are remarkably fast with gorgeous surface quality, I wasn’t able to get precision parts out of it until I turned the flow way down and set up Orca Slicer. Our Torture Toaster, Calibration Castle, and collapsible sword all locked up tight at default settings when using its own slicer. It’s like being given a sports car with bald tires — sure, it’s fast, but it’s no fun to drive if you keep ending up in the ditch.

The printer was also blessed with an overabundance of cooling power, provided by a CPAP turbofan with 40,000 RPM. The fan is tucked into the printer’s upper compartment and blows air down a tube to the hotend. Its ear-piercing, high-pitched whine can be heard from the other end of the house. Reducing the fan to 85% provides enough cooling with a tolerable, yet sadly still annoying, level of noise.

LATEST VIDEOS FROM tomshardware Tom’s Hardware

The FLSun S1 was so large — both in size and weight — I couldn’t set it up in my studio. Though the footprint is just under two feet square, it’s 42 inches tall and can’t clear the RepRack spool shelf I have mounted near the ceiling. The printer weighs 95 pounds, so I had to buy a new heavy-duty shelving unit just to get it off the floor. The IKEA end table I had placed its predecessor, theFLSun V400 , wasn’t sturdy enough to hold it.

This machine has so much wasted potential. FLSun really dropped the ball with their half-hearted custom slicer. Thankfully, I found a profile forOrcaSlicer right before finishing this review that gave me hope the printer can be saved. With a price tag of $1,499, it’s not a printer I’d recommend for beginners, but there’s no denying its speed and futuristic flare. It may not be theBest 3D Printer I’ve seen this year, but it’s definitely the fastest.

Specifications: FLSun S1

Swipe to scroll horizontally

| Build Volume | ⌀320 x 430mm (⌀12.6 x16.9 inches) |

|---|---|

| Material | PLA/PETG/TPU/ABS (up to 350 degrees) |

| Extruder Type | Direct Drive |

| Nozzle | .4mm V6 Hardened Steel |

| Build Platform | PEI Spring Steel, Heated |

| Bed Leveling | LIDAR Auto Leveling |

| Filament Runout Sensor | Yes |

| Connectivity | USB, Wi-Fi |

| Interface | Integrated color touch screen |

| Machine Footprint | 550 x 595 x 1030mm (21.6 x 19.8 x 19.1 inches) |

| Machine Weight | 41kg (90 pounds) |

Today’s best Flsun S1 deals

View Similar Amazon US ](https://target.georiot.com/Proxy.ashx?tsid=45723&GR%5FURL=https%3A%2F%2Fwww.amazon.com%2Fs%3Fk%3DFlsun+S1%26tag%3Dhawk-future-20%26ascsubtag%3Dtomshardware-us-5864181353931501004-20 )

Amazon ](https://target.georiot.com/Proxy.ashx?tsid=45723&GR%5FURL=https%3A%2F%2Fwww.amazon.com%2Fs%3Fk%3DFlsun+S1%26tag%3Dhawk-future-20%26ascsubtag%3Dtomshardware-us-5864181353931501004-20 )

We check over 250 million products every day for the best prices

Power Tools add-on for Google Sheets, Lifetime subscription

Power Tools add-on for Google Sheets, Lifetime subscription

Included in the box: FLSun S1

(Image credit: Tom’s Hardware)

The FLSun S1 comes with everything you need to get started: tools to build and maintain the printer, side cutters, a nozzle cleaner, grease, and a USB drive. You also get a spare hotend kit and a 500 gram spool of filament.

There’s a paper copy of the user manual, and the USB drive has a copy of the FLSun Slicer. Test models are loaded in the printer’s memory.

Assembling the FLSun S1

(Image credit: Tom’s Hardware)

The FLSun S1 arrives mostly assembled. You only need to plug in a few cords, pop the front panel containing the screen on the bottom, then attach the front door.

Warning: The front door is packed in such a way that it appears attached. It is not. If you’re the kind to start ripping off packing material before reading the assembly directions, you’ll be in for a surprise.

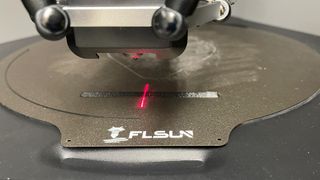

Leveling the FLSun S1

(Image credit: Tom’s Hardware)

The FLSun S1 comes with LIDAR and a host of sensors for automatic bed leveling and calibration. Just push a button, and the machine does the rest. I didn’t have any issues with bed leveling.

If you need to adjust the nozzle height for a pesky filament (like PETG), there’s a limited amount of z height available from the tuning screen.

Loading Filament in the FLSun S1

(Image credit: Tom’s Hardware)

Loading filament in the FLSun S1 is a little tricky due to the perfectly spool-shaped hole in the built-in filament drying on the top of the machine.

I found it necessary to hold the spool in my left hand and feed the strand into the Bowden tube with my right. Once you reach the tool head (several feet of Bowden tube later), you can use the quick release on the tubing and shove the last few inches home.

(Image credit: Tom’s Hardware)

Though I was able to feed TPU the normal way, it’s far easier to use a table mounted spool and use the secondary filament path. You’ll have to turn off the filament runout sensor, which you can do from the control panel.

(Image credit: Tom’s Hardware)

There’s a serious flaw in the Klipper config file that controls unloading filament. The printer doesn’t know to push the filament forward a bit to soften and release it from the nozzle. However, this is easy to fix — if you don’t mind getting into the code.

Here’s what the altered macro looks like:

1 | [gcode_macro UNLOAD_FILAMENT] |

Design of the FLSun S1

(Image credit: Tom’s Hardware)

The FLSun S1 is a delta printer with three slender carbon fiber arms that slide up and down on belt-driven rails. It’s a very tall, very wide machine wrapped in a steel enclosure and weighs about 95 pounds. Prepare accordingly.

It has a sleek, futuristic look with the best control screen I’ve ever seen on a 3D printer. The glass panel blends seamlessly into the machine’s front and offers large, clear text and graphics, including a speedometer to show off how fast the print head is whirling.

(Image credit: Tom’s Hardware)

The spool holder is set inside a built-in filament drier. It can operate while the printer is running or idle, allowing you to prep filament before use or keep it dry during printing. There are no temperature settings for the dryer - just an on/off switch and a timer. A humidity gauge suggests how moist the chamber is but seems to be wildly inaccurate. At one point it said the humidity was 2%, while a separate hygrometer says it was 45%. The temperature is also off by a drastic amount, with the screen saying 54.8C, but it was 80.7F (26.6C) on my thermometer. For the record, we want the dry box to be between 40 and 50C for PLA and up to 65C for PETG.

(Image credit: Tom’s Hardware)

The spindle is mounted on a load sensor to estimate how much of the spool has been used. However, it assumes you’re using an “average” 1kg spool without any way to adjust for the starting weight of the spool or half-sized spools. I think the feature is still useful to give you a general idea of how much material might be left.

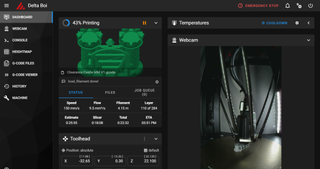

The FLSun runs Klipper with a vanilla Mainsail interface. It comes with a camera mounted inside, so there’s no fuss getting monitoring set up. The camera can also take timelapse videos, but it only saves one at a time. It has a fish eye lens to fit its enormous build volume inside the frame.

(Image credit: Tom’s Hardware)

The machine has two USB ports on the front, and also connects via Wi-Fi.

The FLSun S1 boasts speeds up to 1200mm/s, which it uses for travel moves. Its print speed tops out at 800mm/s and is used for infill. The walls are attempted at 500 mm/s. And I say_attempt_ because running the printer at full speed often results in poor quality or prints knocked off the bed. The photo below shows a sword pommel that was spoiled because the machine vibrated so much the part was constantly wiggling.

(Image credit: Tom’s Hardware)

The S1 uses a CPAP blower to provide the enormous amount of cooling needed for a printer running at these speeds. It’s violently noisy, with a high-pitched whine that makes thinking difficult. Thankfully, you can turn the fan down to 85% to get some noise relief while still cooling your parts sufficiently.

Bed adhesion at full speed is difficult for this printer, despite the nice PEI coating on its flexible plate. The manual advises using glue stick for all prints, but there is no reminder like you would see on the cool engineering plates of other brands. This is a hard lesson to learn, and forgetting is painful. I got a print wrapped around the nozzle so bad it traveled upward into the fan. This required replacing much of the tool head, and FLSun was kind enough to swap out the entire printer and let me try again.

(Image credit: Tom’s Hardware)

That said, the FLSun S1’s hotend is amazing. The throat of the hotend is drilled out like a CHT nozzle to provide high flow, while the nozzle itself is a standard removable V6.

(Image credit: Tom’s Hardware)

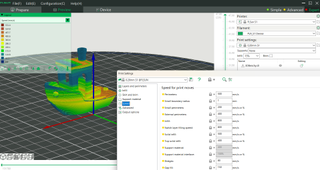

Preparing Files / Software

(Image credit: Tom’s Hardware)

FLSun decided to make its own slicer, piggybacking off PrusaSlicer from the looks of it. The slicer itself is ok, but the presets are lacking. I had to do some serious tuning to get the printer to stop over-extruding and making my ears bleed with fan noise.

A profile for OrcaSlicer has been released to the FLSun Wiki, which helps, but you still need to tone down the fan and filament flow. I set the part cooling fan to 85% and material flow to 0.9, making it more manageable.

Printing on the FLSun S1

Surface quality on the FLSun S1 is very smooth, but the included custom slicer does it no justice. My prints using FLSun’s slicer were terribly inaccurate, horribly over extruded and prone to fails. Switching to OrcaSlicer improved the quality, but I still had to tone down the flow to 0.9 in the filament profile.

The speed boat for this Delta printer is the fastest I’ve printed on any machine. The 500-gram sample spool was more generous than most, but you’ll still want to buy a full-sized spool right away. Check out our list of thebest filaments for 3D printing here.

A Speed Benchy needs to follow certain rules: two walls, three top and bottom layers, 10 % grid infill, a 0.25 layer height, and a 0.5 layer width. Like some of the newer fast printers, this machine is faster than my default settings of 300mm/s. The S1 ripped through the previous record with a blazing 12-minute and 48-second boat, topping our list of thefastest 3D printers .

This boat is a little squashy on the roof, and the porthole is a bit oval. But it’s still a lot better than many speed boats I’ve run in the past year or two.

Remember: When racing a 3D Printer, it’s more about printing a “Benchy Shaped Object” than real quality.

This was printed in ordinarygray Inland PLA , so none of the defects are hidden.

3D Benchy (Image credit: Tom’s Hardware)

I printed a few tests with the sample spool of white PLA provided with the printer. You’ll definitely need to shop for some more. To see my favorite materials to use, check out our guide to theBest Filaments for 3D Printing.

I printed a lot of PLA while testing this printer, but the most frustrating was this collapsible sword with an admittedly difficult hilt. You need a very reliable printer to get these sabers to turn out, but no amount of tuning with the custom slicer was able to make this work, with bits of spaghetti appearing at the top and the blades oozing together at the bottom.

Switching to Orca Slicer finally gave me a print that worked. UsingCreality Hyper PLA , the final sword was printed with a 0.2 layer height at 500mm/s and took two hours and 28 minutes to print. The print was smooth, with no visible layer lines, except for the underside of the guard, where it got a little sloppy. This print would have taken an ordinary bed slinger, like thePrusa MK4 , a little over seven hours to print.

3DPrintingWorld’s Dread Pirate Roberts Collapsing Sword (Image credit: Tom’s Hardware)

The drier came in handy for this PETG print. You can see the improvement in quality, with the undried filament on the left looking a bit rough and the smoother dried print on the right. This print usesGreengate Translucent Purple Petg with a medallion and lid ofPolymaker Gold PLA andProto Pasta Empire Strikes Black . It was printed using FLSun’s slicer turned down to 60mm/s and a pause at height command to swap the filament colors. The jar took one hour and 58 minutes to print, plus another 22 minutes for the lid, and about 6 minutes for the medallion. That’s a little less than two and a half hours of total print time.

Jars made in TinkerCad (Right: undried. Left: dried) (Image credit: Tom’s Hardware)

It did surprisingly well on TPU once I slowed it down a bit. Running the filament through the secondary access point is highly recommended, as that bypasses several feet of Bowden tube. I made this bone shaped dog toy in TinkerCad that turned out with nice smooth layers and a good top finish. I used theInland Rainbow TPU and it printed in 52 minutes at 0.2 layer height and 60mm/s speed.

(Image credit: Tom’s Hardware)

I tested ABS (usingPolymaker Galaxy Orange ABS ) for this RC car part with the custom slicer, and it was entirely too fast – causing poor layer adhesion. It also knocked over the tree supports each of the three times I tried this print. With a bit of tuning, I could make this work. I gave up and printed this part on theQIDI Tech Q1 since I needed it for MRRF and couldn’t waste more of my orange ABS.

(Image credit: Tom’s Hardware)

Bottom Line

The FLSun S1 is a frustrating hunk of machinery that’s so close to wonderful and yet so far from it. No one should pay $1,500 for a machine that needs this much tuning to perform well. The plus side is it runs vanilla Klipper firmware and can be switched to OrcaSlicer for those who don’t mind an expensive tinkering project.

For everyone else, I suggest they wait and see if improvements are made to the firmware to clear out the odd little bugs.

If you’re still interested in a great Delta printer, theFLSun V400 has seen great improvements in its firmware since we reviewed it, and it is on sale for $549. Or if you need a good enclosed printer with a large build volume, I’d recommend theCreality K1 Max , currently going for $759.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers

Flsun S1: Price Comparison

View Similar Amazon US ](https://target.georiot.com/Proxy.ashx?tsid=45723&GR%5FURL=https%3A%2F%2Fwww.amazon.com%2Fs%3Fk%3DFlsun+S1%26tag%3Dhawk-future-20%26ascsubtag%3Dtomshardware-us-5864181353931501004-20 )

Amazon ](https://target.georiot.com/Proxy.ashx?tsid=45723&GR%5FURL=https%3A%2F%2Fwww.amazon.com%2Fs%3Fk%3DFlsun+S1%26tag%3Dhawk-future-20%26ascsubtag%3Dtomshardware-us-5864181353931501004-20 )

We check over 250 million products every day for the best prices

powered by

Also read:

- [New] Brand Differentiation with Powerful YouTube Names for 2024

- [New] From Play to Perfection PS3 Playthroughs Captured for 2024

- [New] Your Path to Perfect Videos with Any of These 7 Free Tools

- [Updated] Seamless Blend Linking Spotify & Discord Directly for 2024

- 2024 Approved Mastering Live TikTok Sessions via Integrated Zoom Platforms

- 2024 Approved Mastering Video Record with VLC

- Advanced Mac Skills Perfecting SRT File Management for 2024

- Asus TUF Gaming A14 Laptop: An Expert Review on Longevity & Endurance in Gaming PCs

- Comprehensive Analysis of the Cooler Master ION 360 All-In-One Liquid Cooling System: Progress and Pitfalls

- Comprehensive Analysis of the Powerful Asus ROG Rapture Gigabit WiFi 7 Router with Unmatched Performance and Scalability

- Comprehensive Review: Unveiling the Capabilities of Free Image Editor PhotoScape

- Diagnosing and Correcting 'Shell.dll' Absence: Tips & Techniques

- Dive Into the Asus ROG Rapture GT-BE98 Pro Wi-Fi Router - The Ultimate Review on Performance and Scalability

- Efficiency and Speed

- Ensuring Smooth Playback of Mobile Video Content

- Expert Analysis of the Dough Spectrum Black OLED Gaming Display - 27 Masterpiece

- Expert Evaluation: The Kensun Portable Air Compressor - Sturdy Performance for On-the-Go Inflation Needs

- Expert Insight on Logitech G515 Lightspeed: Combining Low Profile Style with Cost-Effective Performance

- Exploring the Latest in PC Components with Tom's Hardware Experts

- Finalizing Account Deletion on Instagram Method and Tips

- Hacks to do pokemon go trainer battles For Poco M6 Pro 5G | Dr.fone

- In-Depth Review of the G.SKILL Trident Z5 RGB - The Perfect Companion for Dual-Channel DIMM Configurations

- Is your Huawei Nova Y91 working too slow? Heres how you can hard reset it | Dr.fone

- Mastering 3D Text in Adobe Photoshop for 2024

- Mavic Air Vs. Spark The Gamer's Edition Comparison

- Microsoft Surface Pro and the Copilot+ Experience: Gorgeous Hardware, Yet AI Innovations Leave Something to Be Desired

- Navigating Gadgets with Tom: Your Guide to Computer Components

- Navigating New Tech: Tips and Reviews on Computer Hardware by Tom

- Preventive Measures Such as Protective Eyewear Can Significantly Reduce the Risk of Ocular Trauma

- Revolutionize Your PC Performance: A Deep Dive Into TeamGroup T-Force Dark AirFlow I SSD Cooler Capabilities

- The Best iSpoofer Alternative to Try On Poco C65 | Dr.fone

- The Initial Planning Phase Includes a Detailed Survey of the Property's Physical Features

- The Tom's Innovation Blog: Cutting-Edge Insights on Hardware Solutions

- Tom's Tech Review: Comprehensive Guide

- Tom's Tech Review: The Ultimate Guide

- Tom's Tech Review: Unveiling the Latest in Computer Components

- Top Picks in PC Components by Tech Savvy Tom

- Unboxing the Asus ROG Azoth Extreme: Top Review for Your Money-Saving Search

- Unveiling Top Gear Secrets - Expert Advice From Tom's Hardware

- Title: Comprehensive Reviews and Advice on Gadgets - Trust in Tom's Hardware

- Author: Kevin

- Created at : 2024-08-15 00:32:25

- Updated at : 2024-08-16 00:32:25

- Link: https://hardware-reviews.techidaily.com/comprehensive-reviews-and-advice-on-gadgets-trust-in-toms-hardware/

- License: This work is licensed under CC BY-NC-SA 4.0.

Easy GIF Animator is a powerful animated GIF editor and the top tool for creating animated pictures, banners, buttons and GIF videos. You get extensive animation editing features, animation effects, unmatched image quality and optimization for the web. No other GIF animation software matches our features and ease of use, that’s why Easy GIF Animator is so popular.

Easy GIF Animator is a powerful animated GIF editor and the top tool for creating animated pictures, banners, buttons and GIF videos. You get extensive animation editing features, animation effects, unmatched image quality and optimization for the web. No other GIF animation software matches our features and ease of use, that’s why Easy GIF Animator is so popular.